Tue, Feb 4, 2025

[Archive]

Volume 20, Issue 1 (March 2023)

IJMSE 2023, 20(1): 1-13 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

toufik C, Chibani S, Khireddine O, Boukari A. Adsorption Study of Pb(II) Ions on the Blast Furnace Slag (BFS) from Aqueous Solution. IJMSE 2023; 20 (1) :1-13

URL: http://ijmse.iust.ac.ir/article-1-3011-en.html

URL: http://ijmse.iust.ac.ir/article-1-3011-en.html

Abstract: (9577 Views)

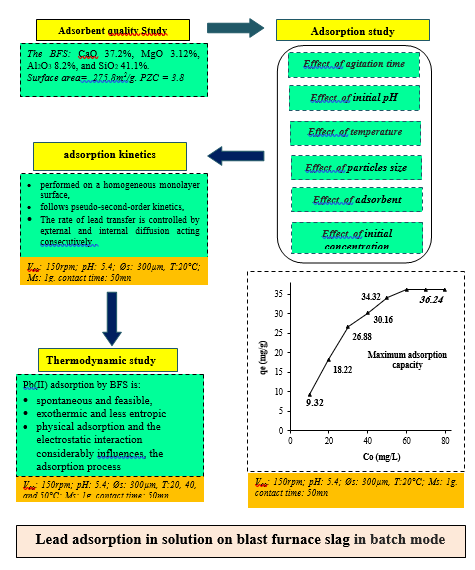

In this work, blast furnace slag (BFS) was used as an adsorbent material for the removal of Pb(II) ions in solution in batch mode. The physico-chemical analyzes used indicated that the BFS is essentially composed of silica, lime, and alumina. Its specific surface area corresponds to 275.8m2/g and its PZC is around 3.8.

The adsorption study indicated that the maximum amount of Pb(II) adsorbed under optimum conditions (agitation speed (Vag): 150rpm; pH: 5.4; particle size (Øs): 300µm, T: 20°C) is 34.26mg/g after 50 minutes of agitation, and adsorption yield is best for feeble initial concentrations. The most appropriate isothermal model was that of Langmuir, and the adsorption speed was better characterized by the pseudo-second order kinetic model. The adsorption mechanism revealed that internal diffusion is not the only mechanism that controls the adsorption process; there is also external diffusion, which contributes enormously in the transfer of Pb(II) from solution to adsorbent. Thermodynamic study indicated that the Pb(II) adsorption on the blast furnace slag (BFS) was spontaneous, exothermic, and that the adsorbed Pb(II) is more ordered at the surface of the adsorbent. Finally, we estimate that BFS is a superb adsorbent for water containing Pb(II).

The adsorption study indicated that the maximum amount of Pb(II) adsorbed under optimum conditions (agitation speed (Vag): 150rpm; pH: 5.4; particle size (Øs): 300µm, T: 20°C) is 34.26mg/g after 50 minutes of agitation, and adsorption yield is best for feeble initial concentrations. The most appropriate isothermal model was that of Langmuir, and the adsorption speed was better characterized by the pseudo-second order kinetic model. The adsorption mechanism revealed that internal diffusion is not the only mechanism that controls the adsorption process; there is also external diffusion, which contributes enormously in the transfer of Pb(II) from solution to adsorbent. Thermodynamic study indicated that the Pb(II) adsorption on the blast furnace slag (BFS) was spontaneous, exothermic, and that the adsorbed Pb(II) is more ordered at the surface of the adsorbent. Finally, we estimate that BFS is a superb adsorbent for water containing Pb(II).

Type of Study: Research Paper |

Subject:

Casting and Solidification

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |